Thursday, May 31, 2012

Four Letter Openers.

Posted by Steve Good at 1:46:00 AM

Wednesday, May 30, 2012

Decorative Fretwork Pattern.

Posted by Steve Good at 1:05:00 AM

Monday, May 28, 2012

Custom paper clock dial from your photo. Order now at this introductory price.

I am excited to start a new service here at the Scrollsaw Workshop. Custom paper clock dials from your photo. The clocks you make from these dials will make wonderful gifts for weddings, anniversaries, birth of a baby and special events. I will also include patterns for two different style clocks for your custom dial. You can also use the dials on any clock pattern you already have. You may need to re-size the dial for some clocks.

I am excited to start a new service here at the Scrollsaw Workshop. Custom paper clock dials from your photo. The clocks you make from these dials will make wonderful gifts for weddings, anniversaries, birth of a baby and special events. I will also include patterns for two different style clocks for your custom dial. You can also use the dials on any clock pattern you already have. You may need to re-size the dial for some clocks.

Please read and understand what you will receive before you place your order:

You will receive 1 digital file by email containing four different size clock dials. If you look at the picture above you will notice that there is a square dial and a round dial. Cut the pattern depending on if you want the round or the square dial. This allows you to print as many of the dials as you need for your projects. Want to make a clock for all the grandchildren? Print what you need.

Please make sure the photo is of good enough quality to print out well. A picture straight from your digital camera will work best. Pictures that you have downloaded from facebook will likely be too small. I'll try to work with any photo you have but the results may vary.

Remember that the photo will be cropped to fit inside the circle. I will position the photo to best fit the space but some photos work better than others. Consider this when you select your photo.

I will do limited photo enhancement so please make sure the photo looks good before you upload it.

Photos will currently only be accepted from the upload form in the provided link. Eventually I hope to accept photographs by mail to be scanned in at an additional cost but that is a few days off.

You will receive links to two different style clock patterns for use with the dials.

Simply print the size dial you wish to use and use spray adhesive to attach the dial to the clock.

Apply several coats of spray acrylic to the clock to seal the dial and finish the clock.

Clocks will require a quartz clock movement to complete.

I will complete the custom paper dial as quick as possible but there may be delays based on my ability to get them complete. I just don't know yet what the demand will be so as I get further along I may be able to give better return times. Each order will contain only one photo. If you want more than one custom dial you will need to fill out an order for each photo uploaded. I will eventually allow multiple uploads per order but I need to start simple.

You will only pay after you receive the dial and are happy with it. I will send the email including the digital file along with a link to pay with your credit card. I will also include my address so you can pay with check or cash.

The price will got up on June 10 to $10 per photo.

Below are a couple examples of what you can do with these custom paper dials. Patterns for both styles of clocks will be included with your order.

Posted by Steve Good at 11:09:00 PM

Remember the fallen on Memorial Day.

Posted by Steve Good at 5:20:00 AM

Sunday, May 27, 2012

Vogmask.com High Fashion Dust Mask.

I was ask by the people at Vogmask to review their fashionable particle mask. I have reviewed masks before but these are definitely the best looking set of masks on the market. Who says you can't look good in the shop? They Sell for $20 shipping included. That price is very reasonable in my opinion.

I was ask by the people at Vogmask to review their fashionable particle mask. I have reviewed masks before but these are definitely the best looking set of masks on the market. Who says you can't look good in the shop? They Sell for $20 shipping included. That price is very reasonable in my opinion. I ask for and was sent the 8bit computer graphics mask. Being an old computer geek I just had to have this one. Watch the video review above for more details. Visit the Vogmask web page and pick up one or two of these fashionable masks.

I ask for and was sent the 8bit computer graphics mask. Being an old computer geek I just had to have this one. Watch the video review above for more details. Visit the Vogmask web page and pick up one or two of these fashionable masks.Posted by Steve Good at 2:12:00 AM

Friday, May 25, 2012

Simple Mallard Scroll Saw Pattern.

Posted by Steve Good at 12:58:00 AM

Thursday, May 24, 2012

Another Custom Clock.

A reader sent me the idea for this clock. Turns out you can disassemble clock inserts and replace the paper dial with a custom one. That fits right in with what I have been working on for my custom paper dial project. All I had to do was re-size the the dial smaller and I was all set. I designed a very simple clock to hold the insert so the picture would be the star and not the wood body.

A reader sent me the idea for this clock. Turns out you can disassemble clock inserts and replace the paper dial with a custom one. That fits right in with what I have been working on for my custom paper dial project. All I had to do was re-size the the dial smaller and I was all set. I designed a very simple clock to hold the insert so the picture would be the star and not the wood body. I used a 3 1/2" clock insert I had in the shop which happened to have a 3 inch paper dial. Apparently that is a common size for the paper dial but you might need to shop around. I think the clocks at this link will work. If someone could verify that for me I will pass on the info to everyone.

I used a 3 1/2" clock insert I had in the shop which happened to have a 3 inch paper dial. Apparently that is a common size for the paper dial but you might need to shop around. I think the clocks at this link will work. If someone could verify that for me I will pass on the info to everyone. I printed the custom dial on gloss photo paper and cut it out with scissors. You will need a 1/4" hole in the center. I used an Exacto knife for that. I just disassembled the clock and and glued the new dial in place.

I printed the custom dial on gloss photo paper and cut it out with scissors. You will need a 1/4" hole in the center. I used an Exacto knife for that. I just disassembled the clock and and glued the new dial in place.

When I get my custom paper dial order form set up this size dial will be included so you will have the option of building this style clock. I'm still a few days away from having everything ready to take orders but I moving forward at least.

Thanks to Michael Moreland for passing this tip on to me. He saw the project done on the Scroll Saw Woodworking and Crafts message board.

Posted by Steve Good at 1:18:00 AM

Wednesday, May 23, 2012

Memory Clock Pattern. My father and uncle as children.

I call this my Memory Clock pattern. I thought I needed a simple clock design for the custom paper dials I will be offering soon. In the picture below I have used an old family photo of my father and uncle. This is just one of many ideas for the custom dials. I think these are going to be exciting projects for you to make. The possibilities are endless.

I'm still working out details of the custom paper dials. I have somewhat solved the problem of it being difficult for you to cut the circular dial. The solution was to get rid of the circle. It's easy to cut out a square so I changed the dials to squares. I have included an example below and in the attached pattern. I have tried a few techniques for cutting out the round paper dials and nothing is as easy as I would like. I'll still have the circle dials available but you will have the option of the easier square dials. It's difficult to see in the picture but I framed out the picture with a 1/4" frame. This is optional but it looks better to my eye.

It's difficult to see in the picture but I framed out the picture with a 1/4" frame. This is optional but it looks better to my eye. I made the clock from 3/4" thick stock to make the wood easier to source. You will need to buy a quartz clock movements with a 3/4" shaft. The movements are cheap and readily available at most craft stores. Notice that I also used a router to add a finished look to the top and bottom.

I made the clock from 3/4" thick stock to make the wood easier to source. You will need to buy a quartz clock movements with a 3/4" shaft. The movements are cheap and readily available at most craft stores. Notice that I also used a router to add a finished look to the top and bottom.

Sorry it's taking a while to get ready to accept orders for the custom dials but I want to get it right before I start. In the mean time I have included the Last Supper dial and a blank dial with this pattern for you to play around with in the mean time.

To make the square paper dial more pleasing to the eye I added a parchment paper background so there was not just the stark white.

Posted by Steve Good at 1:32:00 AM

Tuesday, May 22, 2012

Tom Noller DIY Scroll Saw Dust System.

Tom is a carver who uses the scroll saw mostly to do cut outs for wood carvings. Because he regularly cuts thick material he produces a lot of dust. You can see in the pictures below that he built a dust collection system for his Delta scroll saw. The technique could easily be modified for most other saws. Tom used 1 inch PVC pipe. You can buy 45 degree and 90 degree elbow joints which is how he designed the system to point where it was needed. I like the fact that it is an over/under system. Tom says it does a pretty good job getting most of the dust. You can't expect to get it all with any system.

I like the fact that it is an over/under system. Tom says it does a pretty good job getting most of the dust. You can't expect to get it all with any system. Notice the T fitting for connection to a shop vac. Tom's vac hose fit snugly into the T but you might need an adapter to make yours fit if you want to try this system. You can also see the metal pipe clamps he used to hold the system in place.

Notice the T fitting for connection to a shop vac. Tom's vac hose fit snugly into the T but you might need an adapter to make yours fit if you want to try this system. You can also see the metal pipe clamps he used to hold the system in place.

He intentionally left the piping unglued so he can disassemble when necessary.  The over pick up has a bolt through it so not to suck in any large pieces. You really don't want anything too large getting into your shop vac. In this picture the pipe looks like its in the way of the cutting but that might just be the picture. I didn't get a chance to ask tom if this is easy to move out of the way.

The over pick up has a bolt through it so not to suck in any large pieces. You really don't want anything too large getting into your shop vac. In this picture the pipe looks like its in the way of the cutting but that might just be the picture. I didn't get a chance to ask tom if this is easy to move out of the way. I have tried to DIY dust collection systems over the years but I always come back to the same problem. I can't stand the noise of a shop vac while I cut for long periods. I have never found a safe way to dampen the noise so I have always just put up with the dust. If that is not a problem for you then this looks like it might be a reasonably effective DIY system. It's cheap, easy and Tom says it works.

I have tried to DIY dust collection systems over the years but I always come back to the same problem. I can't stand the noise of a shop vac while I cut for long periods. I have never found a safe way to dampen the noise so I have always just put up with the dust. If that is not a problem for you then this looks like it might be a reasonably effective DIY system. It's cheap, easy and Tom says it works.

Thanks for sharing Tom.

Posted by Steve Good at 2:20:00 AM

Monday, May 21, 2012

Two free paper dials for your clocks.

There are 4 inch, 5 inch and 6 inch paper dials in this pattern. I am working on a collection of paper dials from my own photography and some PD photos. I have about 40 completed now.

There are 4 inch, 5 inch and 6 inch paper dials in this pattern. I am working on a collection of paper dials from my own photography and some PD photos. I have about 40 completed now.

I will be producing a video about the use of these dials. I'll talk about my search for a decent circle cutter. I'm also working on the best way to seal and protect the paper dials as well as other helpful information.

For best results print these on high quality matte photo paper. Use the highest quality settings on your printer. A scrap book paper circle cutter makes cutting them out easier but I have also used scissors and if your careful they can be cut out fine.

I am still working on the custom paper dial project and it looks like it's going to work out. There is still a bit of work to do before I can accept orders for them so I will keep you posted. For those of you who sent pictures to help with the test, thanks. I already have some good feedback from the testers and that is helping a lot. There were a bunch of people who sent pictures that did not get a free dial. Thanks for trying to help but I could only use 5 people and that filled up within minutes after the newsletter went out. Thanks again.

Posted by Steve Good at 12:45:00 AM

Sunday, May 20, 2012

Custom Paper Dial Clock Faces. I need your help.

The clock below is just a demo of a clock pattern that I would include with the purchased custom paper dials. I used a picture of my Mther-in-law and her best friend just to show an example of what can be done. I used Baltic Birch plywood for the test but the final clock should be cut from nice hardwoods.

I would love to hear feedback about what words would be good in include on the clocks, Example like, "BEST FRIENDS", "OUR BABY", "GRADUATION" etc are what I'm looking for.

Here is what I need.

Here is what I need.1. Title the email "TEST DIAL"

2. Attach a digital photo. It needs to be high quality.

Any picture from a decent digital camera should work.

just make sure its set to the highest quality. The better the picture the better the

dial will look.

3. Be prepared to send me feedback.

4. The paper dials need to be printed on matte photo paper. They need to be

cut out by hand. I was able to cut them fine with quality scissors but I need

to know if that works for you. I am looking at scrap booking circle cutters

tomorrow to see if they will work better.

5. If the test goes well I will set up a new email order system to sell the paper dials.

I plan to sell the 3 different sizes above for $7. The dials will be made and emailed

for your approval. If you are satisfied you can send me the money. If you don't like them

then you can keep them and not send the payment.

Posted by Steve Good at 5:33:00 AM

Friday, May 18, 2012

Ron Brown's Famous Key Chain Font 2.0 Review

Back in 2005 Ron Brown published an article in the former Scrolsaw Workshop Magazine(Scroll Saw Woodworking and Crafts). In the article Ron showed a font that allowed you to make key chains. Ron also distributed the font as a computer file. Back then the font had some issues because it was not very legible in some sizes. He eventually let it become freeware and it kind of faded out of sight. He had so many requests for the font that he re-designed it for much better legibility and released version 2. You can buy the new version from www.coolhammers.com The cost of the DVD is $16.95 + SH. With the DVD you get the Key Chain font, Scroll Saw Names Font, Make $20 to $40 per hour with your scroll saw pdf and the instructions for installing and using the fonts. The picture above also shows the DVD for cutting cool hammers which is also available from Ron.

The cost of the DVD is $16.95 + SH. With the DVD you get the Key Chain font, Scroll Saw Names Font, Make $20 to $40 per hour with your scroll saw pdf and the instructions for installing and using the fonts. The picture above also shows the DVD for cutting cool hammers which is also available from Ron. The picture above is from Ron's site and shows the Key Chain's cut from the font. Ron has made and sold hundreds of these key chains and he says the size that sells best is 1/2 inch tall and 3/8 inch thick. When I read this in the instructions that sounded very small but after cutting a few I really like the small size. Of course you can make them any size you want.

The picture above is from Ron's site and shows the Key Chain's cut from the font. Ron has made and sold hundreds of these key chains and he says the size that sells best is 1/2 inch tall and 3/8 inch thick. When I read this in the instructions that sounded very small but after cutting a few I really like the small size. Of course you can make them any size you want.

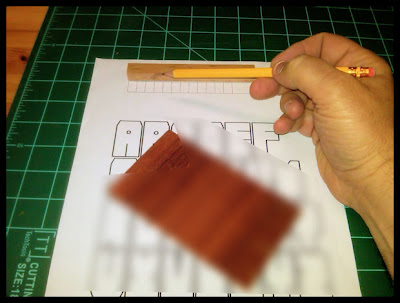

The rest of this post is a demonstration of me using the font and cutting my name. Because of the small size these are a more of a challenge to cut than I thought they would be. They are a blast to make and totally worth the little bit of practice required. For the Key Chains you don't have to apply the pattern to the wood. We are just going to freehand it. Simply type the alphabet into a word processor using the font and print it out for reference. After a while you won't even need the reference.

Because of the small size these are a more of a challenge to cut than I thought they would be. They are a blast to make and totally worth the little bit of practice required. For the Key Chains you don't have to apply the pattern to the wood. We are just going to freehand it. Simply type the alphabet into a word processor using the font and print it out for reference. After a while you won't even need the reference. Ron suggests making a story stick to mark the wood blank. At this size the letters are 5/16 inch in width except for the letter "i" which is about half the width of all the other letters.

Ron suggests making a story stick to mark the wood blank. At this size the letters are 5/16 inch in width except for the letter "i" which is about half the width of all the other letters. You can see here that I have my blank marked. I decided to leave a blank space at the beginning and end but that's optional.

You can see here that I have my blank marked. I decided to leave a blank space at the beginning and end but that's optional. The next step is to cut a shallow line around the blank between each letter. I'm using a #5 blade. Make sure your table is squared up to the blade or your cuts won't line up.

The next step is to cut a shallow line around the blank between each letter. I'm using a #5 blade. Make sure your table is squared up to the blade or your cuts won't line up. After you get all the between letter cuts made it's time to start the letters. I have the printout of the font handy for reference.

After you get all the between letter cuts made it's time to start the letters. I have the printout of the font handy for reference. You want the kerf wide enough to give good legibility. I used a #5 but I might try a #7 next time. Ron's instructions give you tips on how to make the cuts so the key fob stays strong enough not to break.

You want the kerf wide enough to give good legibility. I used a #5 but I might try a #7 next time. Ron's instructions give you tips on how to make the cuts so the key fob stays strong enough not to break. After I have the letters all cut I cut the left over blank away. I found it best to keep it long while I cut to have something to hold on to.

After I have the letters all cut I cut the left over blank away. I found it best to keep it long while I cut to have something to hold on to. A trip over to my mop sander to ease all the edges and it was ready for a finish. You want to do a good job sanding so the key fob feels comfortable in your hand.

A trip over to my mop sander to ease all the edges and it was ready for a finish. You want to do a good job sanding so the key fob feels comfortable in your hand. We are going to use an eyelet screw to attach the split ring so I pre-drilled so not to split the wood. I used a 1/6" bit.

We are going to use an eyelet screw to attach the split ring so I pre-drilled so not to split the wood. I used a 1/6" bit. I decided to finish my key chain with oil and spray acrylic so in it goes for the oil bath.

I decided to finish my key chain with oil and spray acrylic so in it goes for the oil bath. I buy my split rings from Michael's Craft store. A bag of 10 is around $2. You will find them in the leather crafting section. The eyelet screw in this picture was one size too big and I ended up using a small one.

I buy my split rings from Michael's Craft store. A bag of 10 is around $2. You will find them in the leather crafting section. The eyelet screw in this picture was one size too big and I ended up using a small one.

Final Thoughts:

I absolutely enjoyed making these key rings. They are quick to cut, you don't need a pattern and I think they look great. Making these onsite at a craft show or festival would be ideal. Ron says he sells the key chain names for $4 apiece or two for $6. He estimates it takes around 5 minutes to cut the average name. The cost of supplies to make these is very low so when Ron says you could earn $20 to $40 per hour I think that's a fair statement. Of course you have to be at an event with very good foot traffic to stay busy enough to do that.

After you make the purchase from www.coolhammers.com you can opt to have Ron send you the files by email while you wait for the DVD to arrive. He travels a lot so this is not instant but he checks his mail often. My DVD arrived in just a few days.

I really like this product and I definitely think the $20 price is a good value. If you make these as gifts or to sell you will get your money back with just 5 or 6 projects. Visit www.coolhammers.com for more details.

Posted by Steve Good at 3:05:00 AM

Wednesday, May 16, 2012

Are you ready for the sweetest scroll saw tip ever published?

Jim Leasor of Kentucky just sent me this tip. I have not tried it myself but how could you pass this one up? While in the checkout line his daughter wanted some candy. She selected M&M's Minis.

Being a scrollers Jim immediately saw the potential of the packaging. After his daughter finished the candy he took the tube to his shop and did a test fit with one of his scroll saw blades. Perfect fit. The tubes easily hold the blades and they are large enough in diameter to hold bunch.

Jim removed the M&M's label and affixed the label from his package of blades. The tubes also come in multiple colors so you can color code your blades.

I did a bit of searching and it looks like the tubes come in two sizes. 1.08oz and 1.94oz. You need the larger size for the blades. I was thinking the smaller tube might be handy for drill bits. From my searching online it appears that Walmart carries this candy. They seem to range in price from $1.50 to $2.00 per tube. That's not bad considering they come with the candy. I suspect the flap that holds the lid won't last too long but that could be a good thing if you like M&M's.

From my searching online it appears that Walmart carries this candy. They seem to range in price from $1.50 to $2.00 per tube. That's not bad considering they come with the candy. I suspect the flap that holds the lid won't last too long but that could be a good thing if you like M&M's. Jim also whipped up this lazy Susan for the tubes. Thanks for sharing Jim.

Jim also whipped up this lazy Susan for the tubes. Thanks for sharing Jim.

No M&M's were harmed during the research for this post. Many of them have mysteriously disappeared however. Local authorities speculate they melted in the mouth but not in the hand.

Posted by Steve Good at 4:07:00 PM

Cherie Eppler's Zero Clearance Table.

Cherie Eppler is a scroll saw artist from Missouri. She has been scrolling for several years and runs the website CE Woodworks. She recently was a special guest speaker at the NEOS scroll saw picnic. She discussed basic scrolling and zero clearance tables for the scroll saw. The other day she sent me pictures of her new zero clearance table. I thought I would share them with you all.

Cherie Eppler is a scroll saw artist from Missouri. She has been scrolling for several years and runs the website CE Woodworks. She recently was a special guest speaker at the NEOS scroll saw picnic. She discussed basic scrolling and zero clearance tables for the scroll saw. The other day she sent me pictures of her new zero clearance table. I thought I would share them with you all.

The zero clearance table has a few advantages. It provides stability for the pieces when very delicate cuts are made on the scroll saw. It prevents very small cut outs from falling through the hole and into the saw dust under the table. It's like magic when they fall through. You never find them again. Another but some what limited feature is the tear our on the back of some pieces can be reduced.

The pictures below are the table Cherie made for her Shop Smith scroll saw. It is cut to match her table. You will obviously need to cut your table to match your saw. Some scrollers make the table larger to support large pieces of work.

In this first picture she has cut the table to shape and marked the opening for the zero clearance insert. The insert is designed to be replaced as it wears out. In the next picture you see the table with the cutout for the insert empty.

In the next picture you see the table with the cutout for the insert empty. The best way to make the inserts is to mark the position of the blade on the insert then use a #9 blade to cut up the the blade position. This way you can remove the insert with the blade still installed. You might also consider cutting a small finger nail pull area in the upper right part of the insert. This just makes it easier to get in and out.

The best way to make the inserts is to mark the position of the blade on the insert then use a #9 blade to cut up the the blade position. This way you can remove the insert with the blade still installed. You might also consider cutting a small finger nail pull area in the upper right part of the insert. This just makes it easier to get in and out. In the next picture Cherie has the insert installed and is ready to cut. She used double sided carpet tape to hold the table in place. You can get another advantage from a table like this if you devise a method of easily removing the table. After your blade begins to dull you can remove the table and when you start cutting again on the regular table a new set of teeth are exposed. It's like getting double life from your blades.

In the next picture Cherie has the insert installed and is ready to cut. She used double sided carpet tape to hold the table in place. You can get another advantage from a table like this if you devise a method of easily removing the table. After your blade begins to dull you can remove the table and when you start cutting again on the regular table a new set of teeth are exposed. It's like getting double life from your blades. Cherie used 1/8 inch Baltic Birch plywood for her table. She has also tried acrylic but said the tape she uses on her wood tends to stick to the acrylic very easily so she switched to BBP.

Cherie used 1/8 inch Baltic Birch plywood for her table. She has also tried acrylic but said the tape she uses on her wood tends to stick to the acrylic very easily so she switched to BBP.

If you only cut delicate work occasionally you may want to consider a temporary zero clearance. In the picture below I have used a credit card. Just cut into the card about half way and use clear box tape to tape it down.

Posted by Steve Good at 2:55:00 AM

Seyco

Free Pattern Catalog. 1000's of free patterns.

Wooden Vases on the Scroll Saw Book $12 Each

Watch the following video to see how easy these beautiful scroll saw vases

are to make.

Order the $3 pdf Catalog

Stencil Printer Instruction Video.

Scroll Saw Pattern Printer update 1.1

Scroll Saw Keychain Pattern Maker

Use the Scroll Saw Keychain Maker to start a small keychain business. Build yourself a nice display and make up severl keychains with common names. Sell at craft shows, on Ebay or at work. Everyone needs a keychain. Take custom orders. Heck just make them and give them away as gifts. It's all made easy with the Scroll Saw Keychain Maker.

Watch the video demonstration then download the file below and get started with the fun.

Use the Scroll Saw Keychain Maker to start a small keychain business. Build yourself a nice display and make up severl keychains with common names. Sell at craft shows, on Ebay or at work. Everyone needs a keychain. Take custom orders. Heck just make them and give them away as gifts. It's all made easy with the Scroll Saw Keychain Maker.

Watch the video demonstration then download the file below and get started with the fun.

Download the Oval Keychain Pattern Maker.

Philip Lowndes Noah's Arc Pattern Available. Watch the video below.

Think Safety

__________________________

The Scrollsaw Workshop Blog is in no way affiliated with or sponsored by Scroll Saw Woodworking and Crafts Magazine formerly (Scroll Saw Workshop Magazine) or it's publisher Fox Chapel Publishing.

Scroll Saw Woodworking and Crafts