One method of setting the scroll saw blade to 90 degrees is to use a protractor. These things can be expensive. I have seen the plastic ones go for as much as 75 cents. I'm about to save you the burden of spending all that hard earned cash. You can thank me later.

One method of setting the scroll saw blade to 90 degrees is to use a protractor. These things can be expensive. I have seen the plastic ones go for as much as 75 cents. I'm about to save you the burden of spending all that hard earned cash. You can thank me later.

All kidding aside I had a reason to make this gauge. I'm getting older and my eyes are not as good as they once were. I was having a difficult time seeing the green plastic protractor I have. I wanted a white background so the visibility would be better. I was not sure I could get it accurate enough but it was not as difficult as I expected.

This pattern book has the full instructions for making an accurate DIY angle gauge. Believe it or not you can get it very accurate with just a little care. The accuracy of your printer is important. The pattern is best printed on a laser printer but most high quality ink jet printers should work.

Sunday, April 29, 2012

You better sit down because I'm about to save you 75 cents!!!

Posted by Steve Good at 9:25:00 PM

Saturday, April 28, 2012

Video demonstration showing how to make perfectly round wheels on the scroll saw using a sander and a jig.

Posted by Steve Good at 5:01:00 AM

Friday, April 27, 2012

Sending my heart to you.

Posted by Steve Good at 6:53:00 AM

Thursday, April 26, 2012

Display that favorite golf ball.

Posted by Steve Good at 2:34:00 AM

Monday, April 23, 2012

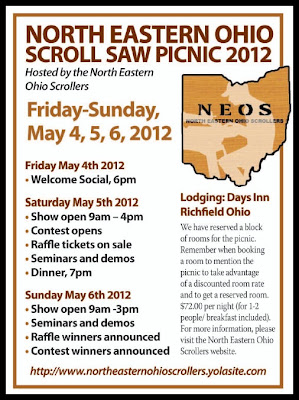

North Eastern Ohio Scroll Saw Picnic 2012.

The NEOS scroll saw picnic is just days away. I just want to ask anyone who can possibly make the trip to please support the efforts of NEOS. These events are expensive for the vendors to travel to and expensive to put on. The work that goes on behind the scenes is extensive and our support is critical for the survival of these shows.

I'll be there Saturday and Sunday and I'm looking forward to meeting everyone. If you see me please come up and say hello. For me the fun of these events is getting a chance to sit and talk with others who share the same interests. Hope to see some of you there.

One more request to any vendors who might like to attend the event. NEOS is still looking for vendors to buy booth space or contribute to the show. I know time is short but this is a great opportunity to meet potential customers for your products. I will also be there covering the show. My newsletter goes out to 12,000 readers and I will be happy to cover your booth or mention your contribution to the show. Just visit the NEOS Web Site and email Lee for details.

Posted by Steve Good at 9:45:00 PM

Sunday, April 22, 2012

DIY Heavy Duty Motorized Turntable. Video details of construction included.

I had some time to tinker in the shop today and I prototyped a project that has been on my list for a while. Several months ago I built a turntable from a small wind up motor. I used the turntable for drying small scroll saw projects after spray finish was applied. I would sit the project on the table, wind it up and let it turn while a fan blew it dry. It worked but it was far from a heavy duty turntable. I wanted something better. I wanted it to be strong enough to turn several pounds. If it would then the turntable could serve a dual purpose. It could still be used in my spray booth but it could also be used to showcase projects in a sales display.

I had some time to tinker in the shop today and I prototyped a project that has been on my list for a while. Several months ago I built a turntable from a small wind up motor. I used the turntable for drying small scroll saw projects after spray finish was applied. I would sit the project on the table, wind it up and let it turn while a fan blew it dry. It worked but it was far from a heavy duty turntable. I wanted something better. I wanted it to be strong enough to turn several pounds. If it would then the turntable could serve a dual purpose. It could still be used in my spray booth but it could also be used to showcase projects in a sales display.

I have been on the lookout for a high torque low rpm motor for some time to build a better version of the turntable. These low rpm motors are hard to find at a reasonable price. I wanted it to be 110v AC so I could just plug it into the wall. Today I stumbled upon the perfect solution. A cheap motor that I could buy locally. The picture above is a rotisserie kit I purchased at Lowes for $30 + tax. The motor runs at about 2 RPM and has enough torque to turn even heavy projects. While I was at Lowes I picked up a 12 inch round table top, lazy susan bearing and I was all set.

The picture above is a rotisserie kit I purchased at Lowes for $30 + tax. The motor runs at about 2 RPM and has enough torque to turn even heavy projects. While I was at Lowes I picked up a 12 inch round table top, lazy susan bearing and I was all set. The video below will give you the details of how I put this project together. There are no plans and you really don't need any. If you plan to use the turntable for display then you will want to build a better looking box to hold the motor and table. I threw this together quickly and was not going for looks, just function.

The video below will give you the details of how I put this project together. There are no plans and you really don't need any. If you plan to use the turntable for display then you will want to build a better looking box to hold the motor and table. I threw this together quickly and was not going for looks, just function.

Posted by Steve Good at 11:48:00 PM

She Said Yes.

Its been a long day for my wife and I. We went to lunch with friends and on the way home we were in an accident. Luckily everyone is okay but my wife had to make a trip in an ambulance to the hospital. She has previous neck injuries that has left her on disability and when we were rear ended she had quite a whiplash.

After a few hours in the ER including a CT scan and X-rays they decided there were no further injury. That was great news but of course there has to be more follow up with her surgeon so we have to keep our fingers crossed a little longer.

The whole incident gave me an up close look at our local Police, Fire and EMTs. It's hard to understand how much you appreciate these guys until you need them quickly. The first police cruiser was onsite within a couple minutes of the accident. The firetruck was only a couple minutes after that. The first officer onsite was quick to get things under control and reassure my wife and I that more help was on the way. The firemen took immediate measure to protect my wife's neck and make sure she was as comfortable as possible. When the EMT's arrived they took over and got her to the hospital quickly.

I drive a Ford F150 Suprecrew and I have to say it held up like a tank. The car that rear ended us had major front end damage but my truck looked undamaged until close inspection. The rear bumper will have to be replaced but unless there is frame damage that's about all that will be needed.

I'm also a big believer in seat belts and today makes me even more so. My wife would have been in the windshield with out the seat belt. We were at a stop and the car that hit us was traveling 20 to 30 mph. The impact was pretty hard.I don't even put a car in drive until everyone has there seat belt buckled. If your reading this please use your seat belt. I truly believe it prevented major injury to my wife and possibly myself today.

I just want to publicly say thanks to the Lexington KY Police, Fire and EMT departments.

Posted by Steve Good at 5:12:00 AM

Friday, April 20, 2012

I don't know what to say about this video. Just watch it.

Posted by Steve Good at 12:51:00 AM

Thursday, April 19, 2012

Graduation Trophies for 2012

Each trophy stands about 9 inches tall. Use contrasting woods so the image of the graduate stands out from the backer. This project requires 1/4" thick and 1/2" thick material.

Each trophy stands about 9 inches tall. Use contrasting woods so the image of the graduate stands out from the backer. This project requires 1/4" thick and 1/2" thick material.

A nice touch would be to customize the project by adding a cutout of the graduates name in front of the trophy attached to base. Just download and use my Scroll Saw Pattern Printer 1.1 available on my blog to create and size the name to fit the base.

Posted by Steve Good at 3:26:00 AM

Tuesday, April 17, 2012

Put a Smile on your desk.

Posted by Steve Good at 3:06:00 AM

Monday, April 16, 2012

Give me coffee and nobody gets hurt.

Posted by Steve Good at 2:33:00 AM

Sunday, April 15, 2012

CorelDRAW Video Tutorial #7

This very simple wooden toy car pattern is part of the CorelDRAW for Scroll Saw Patterns tutorials. In the following video I will show you how to hand trace the outline of the car and create this easy little toy car.

This very simple wooden toy car pattern is part of the CorelDRAW for Scroll Saw Patterns tutorials. In the following video I will show you how to hand trace the outline of the car and create this easy little toy car.

Make sure you click the full screen button to best see the video.

Posted by Steve Good at 1:04:00 AM

Friday, April 13, 2012

P-51 Mustang Scroll Saw Pattern

Several of you have written to ask if I will continue the CorelDraw tutorials. Yes I will continue the series of videos. I have a couple more in the works now and hopefully I can get them posted this weekend.

Several of you have written to ask if I will continue the CorelDraw tutorials. Yes I will continue the series of videos. I have a couple more in the works now and hopefully I can get them posted this weekend.

Posted by Steve Good at 1:05:00 AM

Wednesday, April 11, 2012

Cute Fish Wall Hanging Scroll Saw Pattern.

Posted by Steve Good at 1:45:00 AM

Sunday, April 8, 2012

Decorative Wall Hanging.

Posted by Steve Good at 11:59:00 PM

Saturday, April 7, 2012

Happy Easter.

Posted by Steve Good at 11:26:00 PM

Hold the Presses!

As usual my proof reading skills were not up to the challenge. There is a typo in the Handcrafted by Certificate I published yesterday. The bad news is that I just got new glasses a couple weeks ago so I can't blame it on that. :( I have corrected the error. Please delete the old file and download this one..

Posted by Steve Good at 5:05:00 AM

Friday, April 6, 2012

Handcrafted by Certificate.

When you sell or give one of your scroll saw pieces it's a nice touch to include a Handcrafted by Certificate. The certificate says "This one of a kind item was lovingly created by my hands. My hope is that you get as much enjoyment from owning this piece as I received from making it. Craftsmanship is my goal but you satisfaction in my passion."

When you sell or give one of your scroll saw pieces it's a nice touch to include a Handcrafted by Certificate. The certificate says "This one of a kind item was lovingly created by my hands. My hope is that you get as much enjoyment from owning this piece as I received from making it. Craftsmanship is my goal but you satisfaction in my passion."

I had hoped to distribute this certificate in a high quality vector format but the file size was just too large. I converted it the the highest quality .jpg as possible for printing. It printed pretty well on my inkjet printer so hopefully you will find it useful.

Posted by Steve Good at 1:05:00 AM

Thursday, April 5, 2012

Toymaker Press offers free plans for a limited time.

In exchange for joining their mailing list Toymaker Press is offering this wonderful free toy plan for a limited time. Cynthia ask if I would pass this offer along to you guys and I am more than happy to do so. If you have followed my blog for long you know how much I love the work Cynthia and John do with their toy patterns. The creativity of their toys is incredible. Somehow they manage to add nostalgia and a modern twist to all their projects at the same time. If you are a toy maker or want to be do not miss their website. It is simply the best you will find.

In exchange for joining their mailing list Toymaker Press is offering this wonderful free toy plan for a limited time. Cynthia ask if I would pass this offer along to you guys and I am more than happy to do so. If you have followed my blog for long you know how much I love the work Cynthia and John do with their toy patterns. The creativity of their toys is incredible. Somehow they manage to add nostalgia and a modern twist to all their projects at the same time. If you are a toy maker or want to be do not miss their website. It is simply the best you will find.

If their were ever a mailing list you want to sign up for this is the one. Every project in their catalog is special. They protect your privacy and never sell or share their mailing list with any other vendor.

Go ahead and click this link. Toymaker Press. Look at the top of the page for this special offer.

Posted by Steve Good at 1:05:00 AM

Wednesday, April 4, 2012

Going to Arts and Crafts Shows. A class by Hans Meier.

This video from the GWA meeting in January may be of interest to those of you looking to start doing craft shows. Hans Meier discusses many topics in this very lengthy video.

Your first craft show can be exciting but it can also be a rude awakening if your not knowledgeable of the in and outs of what it takes to get started. Success is in the details and Hans will give you his list of things to help you prepare.

This video is nearly two hours long so you may want to watch it a little at a time. Just jot down the time in the time bar and you can easily go back later to where you left off.

Thanks to the GWA for making their meetings available for all the scrolling community.

Posted by Steve Good at 1:42:00 AM

Tuesday, April 3, 2012

Baylor vs Notre Dame in the NCAA Women's Basketball Championship Tonight. University of Kentucky wins the men's championship.

The University of Kentucky men's basketball team are the 2012 champions. Kansas made it tough in the second half by making a nice comeback but UK held them off to win their 8th championship. Congratulation to the team, coaches and staff.

The University of Kentucky men's basketball team are the 2012 champions. Kansas made it tough in the second half by making a nice comeback but UK held them off to win their 8th championship. Congratulation to the team, coaches and staff.

Posted by Steve Good at 12:52:00 AM

Monday, April 2, 2012

UK vs KU in the NCAA Basketball Championship!

The University of Kentucky and Kansas University square off in the NCAA men's basketball Championship Monday night. These are the two winningest teams in the history of college basketball. Both teams have much to be proud of in this tournament and it should be a great game. As many of you know I live in Lexington KY so my heart is with Kentucky to take home it's 8th national championship. I wish both teams a safe game.

The University of Kentucky and Kansas University square off in the NCAA men's basketball Championship Monday night. These are the two winningest teams in the history of college basketball. Both teams have much to be proud of in this tournament and it should be a great game. As many of you know I live in Lexington KY so my heart is with Kentucky to take home it's 8th national championship. I wish both teams a safe game.

The women's Championship is Tuesday night so I'll do a pattern for them tomorrow. The undefeated Baylor University vs the ladies from Notre Dame. This looks to be a great match-up as the ladies from Baylor try to be the first team to be 40-0 and win a championship. If you have not seen Brittney Griner play then do your self a favor and tune in Tuesday night.

Posted by Steve Good at 1:34:00 AM

Heritage Wood Specialties. Scroll saw ready boards!

Heritage Wood Specialties is a nationally recognized supplier of superior quality hardwoods to fine woodworkers across the US and Canada. Novice hobbyists and experienced enthusiasts alike can enjoy the high quality woodworking materials and kits available from Heritage Wood Specialties. Great source for scroll saw ready boards.

Seyco

Free Pattern Catalog. 1000's of free patterns.

Wooden Vases on the Scroll Saw Book $12 Each

Watch the following video to see how easy these beautiful scroll saw vases

are to make.

Order the $3 pdf Catalog

Stencil Printer Instruction Video.

Scroll Saw Pattern Printer update 1.1

Scroll Saw Keychain Pattern Maker

Use the Scroll Saw Keychain Maker to start a small keychain business. Build yourself a nice display and make up severl keychains with common names. Sell at craft shows, on Ebay or at work. Everyone needs a keychain. Take custom orders. Heck just make them and give them away as gifts. It's all made easy with the Scroll Saw Keychain Maker.

Watch the video demonstration then download the file below and get started with the fun.

Use the Scroll Saw Keychain Maker to start a small keychain business. Build yourself a nice display and make up severl keychains with common names. Sell at craft shows, on Ebay or at work. Everyone needs a keychain. Take custom orders. Heck just make them and give them away as gifts. It's all made easy with the Scroll Saw Keychain Maker.

Watch the video demonstration then download the file below and get started with the fun.

Download the Oval Keychain Pattern Maker.

Philip Lowndes Noah's Arc Pattern Available. Watch the video below.

Think Safety

__________________________

The Scrollsaw Workshop Blog is in no way affiliated with or sponsored by Scroll Saw Woodworking and Crafts Magazine formerly (Scroll Saw Workshop Magazine) or it's publisher Fox Chapel Publishing.

Scroll Saw Woodworking and Crafts