My wife informed me it was time to build another toy box. Our great-niece Aubrey is about to turn one. Over the years I have built either a rocking horse or toy box for the kids as they turn one. I always try to use the scroll saw to customize the toy boxes with ornaments and names.

I thought some of you might interested to see my progress as I go along. This is my day one progress. I pretty much have the box pieces cut. If I don't get called in to work tomorrow I'll start with the detail work. When I have everything finished I'll publish all the dimensions for the box. I'll also make a few different ornamentation so you can make your own custom toy box.

I visited my local Home Depot and picked up five sheets of 2' X 4' X 3/4" MDF. I plan to paint the final project so MDF is a good choice over plywood. MDF is very heavy but it paints well and it's pretty easy to work with. I'll be using pocket hole joinery for construction.

From my drawing I start cutting down the MDF to size. Remember, MDF is not good on the lungs so make sure you use your dust mask and have your shop well ventilated before you start.

Here are the outside walls of the box cut to rough size. I'll cut the lid and bottom later once the box is assembled. It's easier to cut those pieces to size by measuring than to cut them from the drawings. You can adjust the size if needed that way.

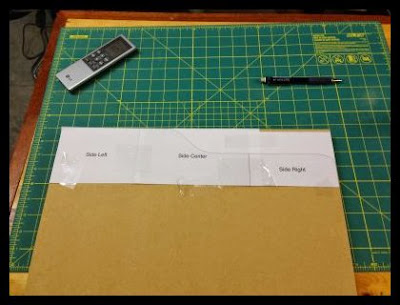

My drawings have the template for the curves of the side and back walls. My plans are printed on 8.5 X 11 paper so I'll have to cut and assemble the template. The picture is for one of the side walls.

In this picture I have the template taped together and ready to apply to the side wall.

I carefully tape the template to one of the cut side walls. Just put the tape on the bottom of the template so you can lift the top in insert the carbon paper. Double check that you are putting the template on the top of the side wall.

You can use carbon paper to trace the template lines but I just use a sheet of paper with pencil. It works fine.

Carefully trace the template curves on to the side wall. You can lift the template and make sure you have a good tracing before you remove the tape. You don't have to be perfect here. You are going to have to sand the final curve anyway to get it smooth.

Once you have a good tracing you can remove the template. If you need to, go over the tracing again to get a line you can see easily.

I'm going to use a jig saw to do a rough cut of the curves. Stay just outside the template line. We will sand the curves to their final finish. Make sure you clamp the piece to your workbench. You want to make as smooth of a cut as you can so you don't have more sanding than necessary. By the way, I'm using my new 20v cordless DeWalt jig saw. I now have the drill, circular saw and jig saw. These tools have power to spare. I'm really impressed with these products.

I finished the rough cut with the jig saw. Now it's over the the spindle sander.

A spindle sander is the right tool for this job. If you don't have one then just sand by hand until you get a nice smooth curve. Take you time here and get it right.

Even with the spindle sander I still finish off the sanding by hand.

Now we can use the finished side to trace the pattern on to the other side.

Make sure the sides are lined up well then just trace the curves.

Just follow the same procedure to cut this side with your jig saw.

I placed both sides in my workbench vice and made sure they matched. If not more sanding is required.

Here is a dry assembly of the progress so far. The next step is to put the curve on the back wall.

The technique for the back wall template is the same as done with the sides. I just cut the pieces and taped them together.

Carefully apply the template. You want to make sure that each end of the curve is lined up with where the side wall meets the curve. You don't want the side wall higher than the back curve.

Back to the jig saw. Follow the same procedure as the side wall. Cut just outside the line. Sand to the line. Get this curve as smooth as possible. It's a long curve and defects will show.

I like to do several dry assemblies as I go along. It's better to spot errors now than after everything is screwed together. Next I'll cut the finger hole on the front.

Measure over four inches from each end and make a mark. Measure down 1.5 inches at each end and make a mark. Connects these lines with a curve. I used a candle jar I had available to mark the curve.

MDF dust if fine and will make a terrible mess of your shop. As I make the cuts with the jig saw I keep my shop vac running to grab as much dust as possible. Remember that dust mask. This stuff is really not good for you. Just like the other pieces use your spindle sander and sand paper to get the front finger hole smooth.

I do another dry assembly. Looking good so far. Fingers crossed.

Pocket hole joinery is my favorite for this type of project. It's easy, It's strong and it's fast. It's so strong that I won't even use glue. MDF does not take glue on it's edges very well so I'll just depend on the pocket screws to keep things together.

Mark the position of your pocket holes before you start to drill. It's too easy to make a mistake and place a hole on the wrong side. You don't want to have to cut another piece at this point. Just take the time to lay out the holes and save yourself the headache.

I cut three pocket holes on each end of the front and back panels. Make sure the top pocket hole is lower than where the lid will fit. To attache the bottom I cut two pocket holes in the side wall and three in the front and back. Some people like to use more but in my experience they are so strong why cause your self more work than needed. I plan to fill the holes and sand them flush so I will keep them to a minimum.

When you start drilling the screws into the panels they have a tendency to move. The Kreg pocket hole system has several different types of clamps. When possible use these clamps to keep things nice and flush. All I'm assembling right now are the walls. This will give me the measurements for the lid and bottom panel.

I measured and cut the bottom panel to give me a 1/2" overlap around the bottom of the box. I'll use my router to put a round-over later. I also measured and cut the lid. I cut the lid just short of the front length to make sure it does not bind when opened. I also cut the lid so it overhangs the front panel by about 1/4".

That's enough for this day. I spent about four hours to get to this point. I have some decisions to make before I start again tomorrow. Hinges, casters, paint color and more need to be worked out. If I don't get called in to work tomorrow I'll see what progress I can make. The final plans for this toy box might take a few days after I get it completed. I want to make sure I have everything where I want it before I do the final design work. I tend to make changes as I go on work like this.