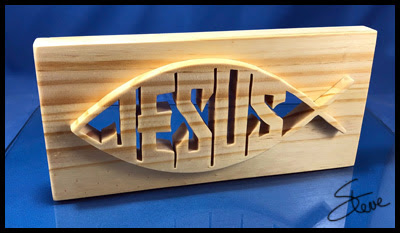

Bevel cut Ichthys. This board is 8.5 inches X 4 inches X 3/4". The internal letters are cut with the blade set at 90 degrees to the table. The table/head is then tilted a to a small angle and the exterior of the ichthys is cut. The ichthys then is pushed out until it wedges in place. Details in the pattern.

Pegas Upgrade Blade Clamp Heads: In-depth review.

I received a set of the Pegas Blade clamps for review. You may have seen them advertised in the latest edition of Scroll Saw Woodworking and Crafts magazine. These new heads are replacements/upgrades for the Excalibur, Excelsior, Seyco and King and Jet scroll saws. I have put them on my Excalibur, Seyco, Jet and DeWalt saws. The DeWalt is not officially supported but I installed them anyway to see what would happen.

If you own or are thinking about the Jet JWSS-22, make sure you read that section. It is significant. Top blade feeding is now supported with this upgrade.

I will talk about this upgrade on the Jet JWSS-22 saw at the end. In my opinion this upgrade has the most impact on the Jet saw.

The ad copy from Pegas reads like this

40% lighter

Reduces vibration

Ease of use.

Reduces stress on the machine increasing the life of the machine.

Changing blades is easier and faster.

The kit comes nicely packaged with everything you need including a set of thumb screws. There wer no instructions in the box but replacement is simple.

To remove the hold head you simply remove the two bolts. Removal required a 3mm allen wrench and a 7mm open end for the nut. After you remove the bolts slide the head off. Pay attention because the head captures two bearing in the arms. Remove the bearings.

The kit comes with new bearings. Install the head and insert the bearing and bolt through the head and arm. Don't over tighten the bolts. Just snug them down.

I started on the Excalibur. After installing the head I ran the machine for several minutes. Everything ran fine. The only slight problem I had was that the tension arm poped up a little just when the saw started. It did not come up enough to change the tension but I need to troubleshoot that when I get a chance. That did not occur on the other two machines I tested.

I installed on the DeWalt second but I'll talk about that below.

I did the next installation on the Seyco ST-21. I ran the Seyco with the new clamps for several minutes and again everything went fine. I did not experience any issue with the tension lever popping up.

Let's talk about the DeWalt for a minute. Pegas does not mention the DeWalt as a machine these clamps are compatible with. If you should try them on your DeWalt I don't expect you will get any support.

The DeWalt is different because of the upfront tension lever. If you use the new Pegas heads you will have two tension levers. I got around this by using the built in tension lever as a rough adjustment. Then I could use the new tension lever to apply the final tension. This seemed to work fine.

Let's talk about the advertising claims.

Weight: 40% lighter

I spoke with a friend down in Atlanta about how important the weight is at the end of the arm on reliability. Bob has torn apart more scroll saws than anyone I know. I consider him as good of an expert as there is for actual real world problems.

Bob is convinced that any extra weight at the end of the arm is definitely a factor on the life of the hardware in the saw. Especially bearings. He has tested this through lab measurements and real world cases.

So with that said how much difference did I measure in the new Pegas heads and the Seyco ST-21 heads. Pictures below.

The complete set of Seyco heads weighs in at 131 grams.

The complete set of Pegas replacement heads is 88 grams.

My math stinks but I think that calculates to the Seyco heads being 48% heavier than the Pegas heads.

I would need much more information to be able to put a number on how much that weight difference makes in reliability.

Without more information from the manufacturer here is my guess. If you use your scroll saw every day for a few hours (Believe or not there and scrollers out there cutting full time) then I believe the impact on your machine would be significant. I am making that guess based on real world cases where full time scrollers use large aluminum knobs on the thumb screw. The large knobs are for comfort and that's great but they do see increased worn out parts from the extra weight.

If you are a weekend scroller or less, then I suspect the impact of this upgrade on reliability will be minimal unless you keep the machine for years.

Vibration:

The following pictures are my test in the shop on these machines with and without the new Pegas heads. This is far from scientific. This is just a measurement. I used a vibration meter app to measure the z axis vibration while each machine was running at it's full speed.

The results are strange and this could be explained by several factors including just being a bad test. It also might be accurate. You decide.

The Excalibur and Seyco both showed more vibration in the z axis(up and down) by a significant percentage. Let me explain what that means. It is significant only in the percentage of the number. Real world, I could not feel the difference in vibration while cutting. I could only see it on the meter.

With either set of heads installed both machine ran smoothly.

Surprisingly the DeWalt DW788 showed a slight improvement with the new Pegas heads. Also notice that this specific DeWalt saw showed considerable less vibration than the other two saws. This DeWalt saw is over ten years old. It is a type one and has always ran extremely smooth. When I compare it to other DeWalts is has the lowest vibration I have seen. Unfortunately this is not the norm.

My conclusion from this vibration test is, I don't know. My assumption was that with the reduction in weight I would see a reduction in vibration. Bad test? I just don't know.

Excalibur Old Clamp

Excalibur New Clamp

Seyco Old Clamp

Seyco New Clamp

DeWalt Old Clamp

DeWalt New Clamp

Ease of Use:

This claim from Pegas is one that I don't know what functionality they are talking about. Functionally they work the same. You clamp the blade with the thumb screw and flip the tension lever.

The tension lever on the Pegas head has a very smooth action. The blade seats nicely and there is a locking screw on the set screw opposite the thumb screw. It works great but I would not consider it easier in any significant way.

Reduces stress on the machine:

I have already covered what I think about the reduced stress from the lighter weight. I believe that claim, I just can't put a number on it.

Faster blade changes:

The only time I can think that the blade changes would be faster is if you installed the new clamp heads on the Jet. On that machine you would eliminate having to use a tool to change the blade in the lower clamp. That's a bit of a reach but I guess that counts.

Now let's talk about this upgrade on the Jet JWSS-22 scroll saw: Big change.

This is a significant change to the Jet scroll saw. The clamp system on the Jet is very unique. It seems to be a love hate thing for users. I personally liked the upper clamp and disliked the lower clamp. The system does not allow for top feeding the blade. That alone eliminated about 40 percent of potential users. The lower clamp required you to remove the chuck and use a tool to replace the blade. The excellent design of the upper clamp was somewhat offset by the lower clamp.

This upgrade changes things entirely. Now top feeders are welcome. If you own the Jet saw you will have to decide if the top clamp design is worth the hassle of the lower clamp. You have to change both the upper and lower clamp when you upgrade so you can't have the old upper clamp and the new lower clamp. That's a shame.

I am going to leave this clamp on my Jet saw. As much as I liked the upper clamp design this is better for me.

For my money I would call this Pegas head assembly kit the Jet JWSS-22 upgrade kit. I think it is that significant for the Jet.

Conclusion:

This upgrade sells for $90. You can purchase it at Bear Woods.

If you own a Jet scroll saw and have a problem with the lower clamp then this is a great upgrade kit. If you were a top feeder and are struggling to convert over to the bottom feed on the Jet then this is a must upgrade. Worth every penny.

If you own an Excalibur, Seyco, Excelsior or King then the choice is a little tougher. It's well made and works fine. If it proves out that it increases the life of the saw then it's good insurance. Some guys have their saws rebuilt several times until they scrap them out. You will have to decide from this review what that increase in life will be. I can't give you an answer on that.

If you own the DeWalt I would say don't buy. It's not officially supported and I can't tell you if it will work without issues. I tried it for a few minutes and it worked. That's all I can say about that.

P.S. I spoke with Ray at Seyco about the impact installing this on the Seyco ST-21 would have on warranty. He told me he would not automatically void a warranty over the installation. He would need to make a determination on each case as to if the upgrade played a part in the failure. If he determined it was the cause then there might be a chance the warranty would not cover the repair.

I suspect that will be the same experience with the other companies but you should check. Just make sure you keep the old clamp assembly in case you need to send the machine in for repairs.

Email Newsletter Readers: Remember that the Newsletter is just a copy of the daily blog post. To see the post in it's proper formatting click this link. If you ever misplace a pattern or any item you see here you can always find it on the blog. Everything stays on the blog forever.

your source for Pegas scroll saw blades and craft supplies.

Visit Heritage Wood Specialties

for your scroll saw ready boards.

Let me teach you to create a beautiful wooden portrait pattern. I will show you everything you need from start to finish. The video will show you the free software program you can download for Windows or Mac OS. I will show you how to install the program and configure it for best results.

Then I will show you the technique to take your photograph and make a pattern from it. When the pattern is complete we will go in the shop and cut it.

The DVD is $10 plus shipping. This is a data DVD that you will use on your computer to watch the video tutorial

Purchase the entire Scrollsaw Workshop pattern catalog for offline access.

This DVD has 2,300 patterns published from 2007 thru 2017.

The DVD is $20 plus shipping. Ships to 60 countries around the world.

The DVD is $20 plus shipping. Ships to 60 countries around the world.

If you use the DVD on a Windows PC there is a simple viewer program to browse through the patterns.

The DVD also works fine on a MAC. The viewer program is not MAC compatible but there is an included PDF with all the patterns shown as thumbnails for easy viewing.

My two "Wooden Vases on the Scroll Saw" books make it easy.

The books are $12 each and available for instant download after purchase. Click for Video

Demonstration.

Ad: Affiliate

Ad: AffiliateMachinist's Thin Parallel Bar Set - 10 Pair 1/8" X 6"

- Our Part # ALL-54100

- Each parallel is 1/8" thick x 6" long with 2 holes

- Includes 10 pairs of the following heights: 1/2", 5/8", 3/4", 7/8", 1", 1-1/8", 1-1/4", 1-3/8", 1-1/2" & 1-5/8"

- Made from high quality tool steel- stress relieved against distortion, precision ground and hardened Parallel and accurate within +/- .0002" and made from high quality tool steel- stress relieved against distortion, precision ground and hardened