This Angel Christmas Tree Topper is a little over seven inches tall. A simple wooden ring glued to the back of the angel is used to slide it over the tree top.

I thought I was about finished designing Christmas themed patterns for the year. We are getting deep into the season. I was doing a seminar the other day and a friend asked for a tree topper. Rob, this one is for you. Hope it's what you were looking for.

I thought I was about finished designing Christmas themed patterns for the year. We are getting deep into the season. I was doing a seminar the other day and a friend asked for a tree topper. Rob, this one is for you. Hope it's what you were looking for.

When is vibration not your scroll saws problem?

When you are cutting delicate fretwork, vibration is a problem. All scroll saws produce some vibration. The better-built scroll saws try to minimize it as much as possible and are pretty effective.

There is a situation where you will experience vibration that is not caused by the scroll saw at all. If you are new to the scroll saw you may not even recognize why you are having the vibration. Let me explain.

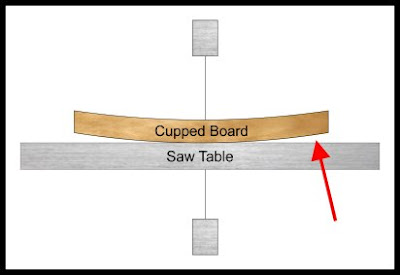

A cupped, twisted or bowed board will rattle as you cut it and give the same experience as a mechanical saw vibration. Sometimes the cup can be minimal so you may not have recognized it was not laying flat on the saw table.

Of course, the best solution to this problem is to cut flat boards. Good luck with that. Wood likes to move as the humidity changes in your shop. A board that was flat yesterday may not be flat today.

There are ways to minimize the vibration while cutting a cupped board.

Once you realize the board is not laying flat on the table you can change your hold on the board and keep it against the table at the spot where the blade goes through the table. This will often require you to move your fingers very close to the blade. This makes some new scrollers nervous but it is quite safe. I will often have my fingers a few millimeters from the blade. If you try to hold the board in the picture above at the edges you will have excessive vibration. I see this often with new scrollers.

Your goal is to put the downward pressure of your fingers as close to the area of the wood that is being cut as possible.

In this picture, the board has been placed on the table with the cup up. While this looks like it might make the problem better it can actually be worse. The board won't wobble in this position but there is no support below the board at the point the blade is making the cut. This is especially bad if the board is thin. This is often more difficult to troubleshoot because the vibration will be there but the board will not give the hint wobble.

The picture above and the one below show the cupped board being held at different angles to make a cut. The difference is slight but the top picture will produce much more vibration. By lifting the board slightly and eliminating the gap between the board and table near the blade to will reduce the vibration.

You have to adjust the board constantly while you make your cuts to keep it against the table. Most of the time this is annoying but with a little practice, you can get through the cut.

There are some patterns that are complex enough, to begin with. Choosing a board that is flat for these more complex cuts is worth the extra effort. It is not uncommon for me to lay a board on my table saw and check for flatness before I put a pattern on it.

The next time you start to feel excessive vibration check your board for flatness.

Email Newsletter Readers: Remember that the Newsletter is just a copy of the daily blog post. To see the post in it's proper formatting click this link. If you ever misplace a pattern or any item you see here you can always find it on the blog. Everything stays on the blog forever.

Scroll Saw Pattern Design Tutorial: DVD

Let me teach you to create a beautiful wooden portrait pattern. I will show you everything you need from start to finish. The video will show you the free software program you can download for Windows or Mac OS. I will show you how to install the program and configure it for best results.

Let me teach you to create a beautiful wooden portrait pattern. I will show you everything you need from start to finish. The video will show you the free software program you can download for Windows or Mac OS. I will show you how to install the program and configure it for best results.

Then I will show you the technique to take your photograph and make a pattern from it. When the pattern is complete we will go in the shop and cut it.

The DVD is $10 plus shipping. This is a data DVD that you will use on your computer to watch the video tutorial

Every Scrollsaw Workshop Pattern from 2007-2017 in DVD

Purchase the entire Scrollsaw Workshop pattern catalog for offline access.

This DVD has 2,300 patterns published from 2007 thru 2017.

The DVD is $20 plus shipping. Ships to 60 countries around the world.

The DVD is $20 plus shipping. Ships to 60 countries around the world.

If you use the DVD on a Windows PC there is a simple viewer program to browse through the patterns.

The DVD also works fine on a MAC. The viewer program is not MAC compatible but there is an included PDF with all the patterns shown as thumbnails for easy viewing.

My two "Wooden Vases on the Scroll Saw" books make it easy.

The books are $12 each and available for instant download after purchase. Click for Video Demonstration.

My Sponsors:

Support the businesses who support our community.

Home of Pegas scroll saw blades.

Ad: Affiliate

Ad: AffiliateDEWALT DW788 1.3 Amp 20-Inch Variable-Speed Scroll Saw

The current price on Amazon is $429. That is as low as it has been for a while. If you are looking to buy this popular saw this is a good time to check it out.

- Double parallel-link arm design dramatically reduces vibration and noise for extremely accurate cuts

- Exclusive tool-free blade clamps allow blade changes in seconds. Depth of Cut (inches): 2 in

- On-off switch, electronic variable speed, flexible dust blower, and blade-tensioning lever all located on front upper arm

- Arm design pivots from back of the saw to front, shortening the arm movement for smoother, quieter operation

- Arm lifts so blade can be easily threaded through the material for inside cuts